How you can benefit from vacuum packaging

- Removal of oxygen leads to longer shelf life

- Preventing oxidation retains the nutritional value, substance and flavor in food for longer

- Protection against moisture and drying out maintains product quality

- Cost reductions thanks to larger volumes at lower prices

- Limiting the packaging size to the size of the product leads to lower space requirements

- Better hygiene through protection against contact and contamination

- Light protection with UV-resistant packaging

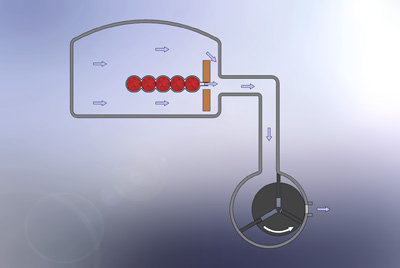

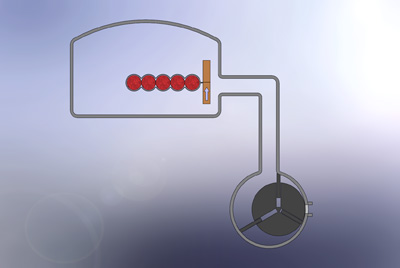

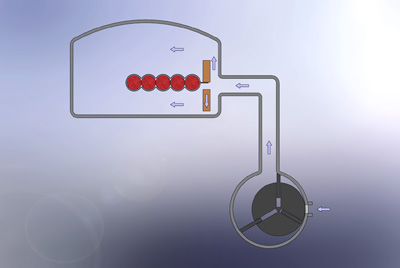

How do vacuum chamber machines work?

The filled and open pouch is placed in the vacuum chamber machine and the lid of the chamber is closed. The vacuum chamber is now a hermetically sealed space. The vacuum pump then extracts the air present in the chamber, pouch and spaces in the product to a predefined value. Once the desired vacuum is reached, the open side of the pouch is permanently sealed. It is now impossible for air to penetrate. The ambient air is then released into the chamber. Once the pressure is equalized, the chamber can be reopened and the fully packaged product removed.

Do you have any questions or need advice?

Just give us a call! We'll be happy to help you.

What can we do for you?

+49 8304 929190

References